Compliant Mechanism

Compliant Mechanism

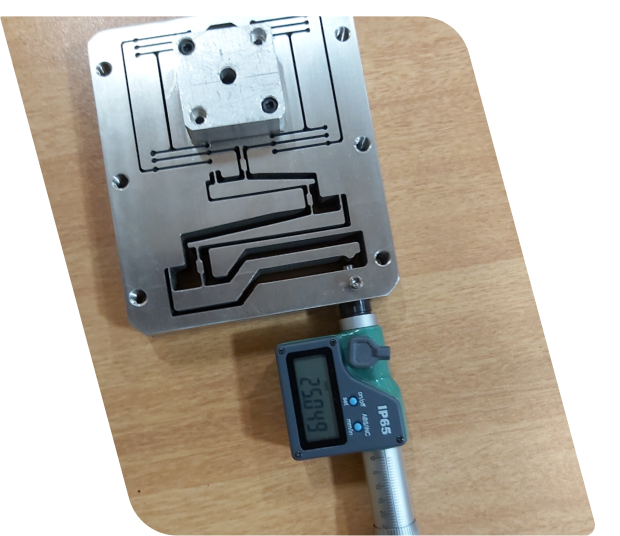

To provide a smooth and exact motion, high-precision hardware, bearings, tolerances, and machined parts are often preferred. One may take advantage of the material’s elastic qualities and carefully construct a compliant mechanism for microscopic motions. Making a working component from a single block of material is possible with the help of the compliant mechanisms; this greatly lowers the number of components (to just one!) and gives outstanding precision (since now there is no need for loose coupling between holes and pins).

In the context of the flexural hinges used in high-precision devices, the optimisation concept is used to optimise the stress levels (and hence the fatigue lifespan) of a hinge for a certain amount of deflection. Hysteresis, overload sensitivity, temperature sensitivity, limited range of motion, etc., are all problems that might arise with the compliant guiding systems.

Technical Specification of the NanoPositioning Compliant Mechanism (Flexure)

- Invar 36

- Has 6 threaded holes for mounting base

- 5 holes with a counterbore for mounting mirror mounts.

- Outer mounting holes will match optical table specifications.

- Travel range: 35 microns

- Travel resolution: 10.5 nm per step

- Input is given via a digital micrometer

- Carried out via Laser interferometry before dispatch

Related Products

Frequently Asked Questions

What is Winding Guru?

Winding Guru is our in-house developed Filament Winding Software designed to simplify and optimize composite winding processes.

What types of structures can Winding Guru handle?

Winding Guru supports various structures, including cylinders, tapered cylinders, rectangular pipes, domes, and more.

Is Winding Guru user-friendly?

Absolutely! Winding Guru features an intuitive interface with interactive 3D visualization for easy pattern generation.

Can I customize winding patterns with Winding Guru?

Yes, Winding Guru offers customization options for winding angles, layer thickness, and winding profiles, ensuring tailored results.

Does Winding Guru support both geodesic and non-geodesic winding?

Yes, Winding Guru accommodates both geodesic and non-geodesic winding techniques for versatile composite designs.