VR NDT Thermographic NDT

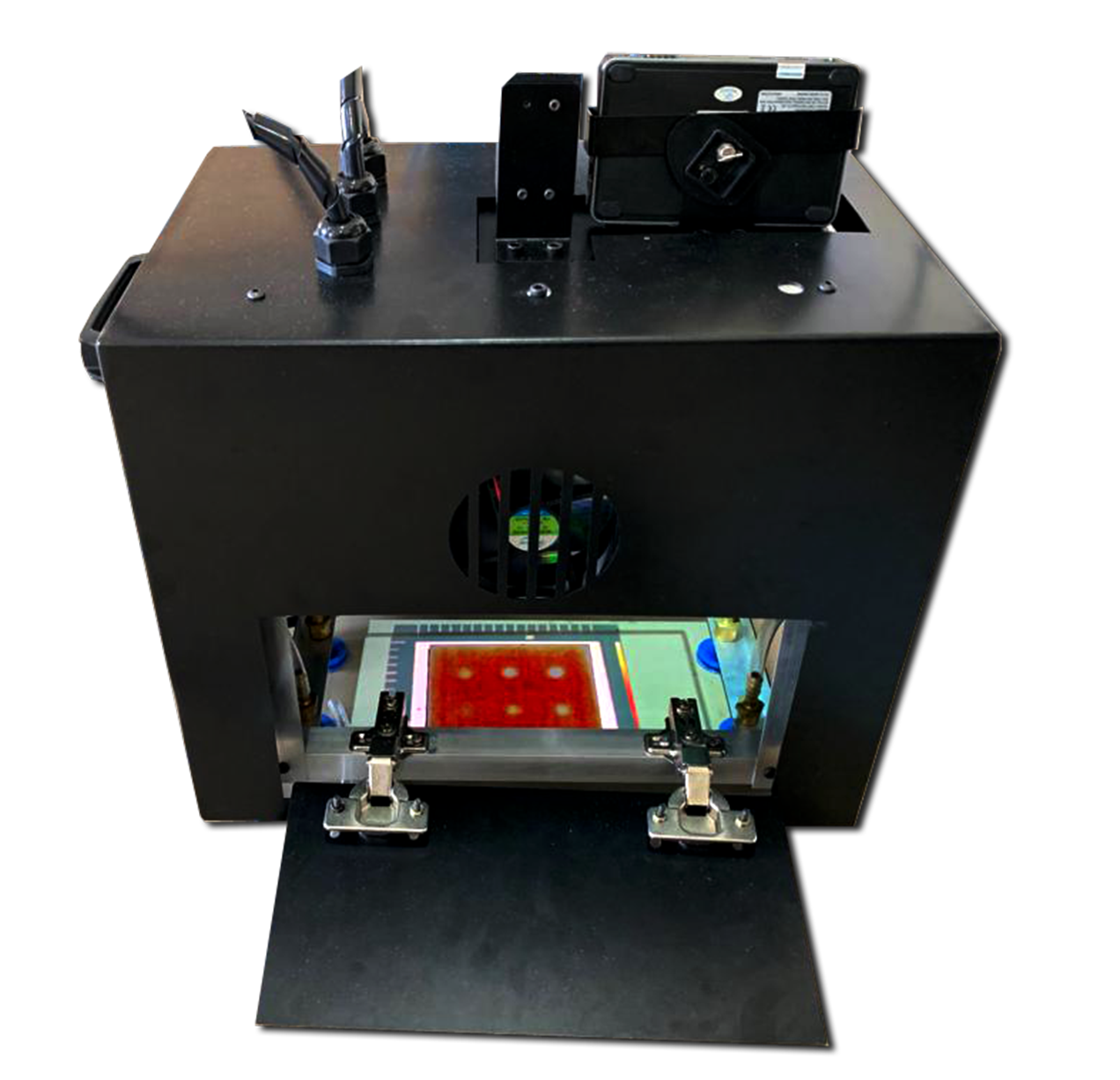

Our Thermographic NDT system VR NDT is a cutting edge technology that uses thermal data to detect surface defects in composite and metallic materials. The thermographic NDT uses an active thermal excitation generated by out thermal source (halogen lamps) that are controlled using our in house developed controller for producing thermal fluctuation in the material. By studying this thermal disturbances produced throughout the material and also using the properties of the disturbance produced, we can identify defects, its size and depth information using our NDT software.

Features

The software features option for different types of simulation ranging from sinusoidal, chirp to digital signals, which are useful for different materials and measuring parameters. Along with the wide variety of signals the software also features multiple data processing algorithms that provide the user a richer variety of data analysis.

The system is useful for finding manufacturing defects such as dis-bonding, inclusions and voids in composites, to see the dis-bonding between 2 different layers in sandwich structures and also manufacturing defects in metals.

Related Products

Frequently Asked Questions

What is VR NDT Thermographic NDT?

VR NDT Thermographic NDT is an advanced non-destructive testing (NDT) system that uses thermal data to detect surface defects in composite and metallic materials.

Can VR NDT Thermographic NDT be used for quality control?

Yes, the system is ideal for quality control applications, allowing manufacturers to ensure the integrity of their materials and identify defects early in the production process.

What types of defects can VR NDT Thermographic NDT detect?

The system is capable of detecting defects such as dis-bonding, inclusions, and voids in composites, as well as identifying dis-bonding between layers in sandwich structures and manufacturing defects in metals.

Is VR NDT Thermographic NDT suitable for composite and metallic materials?

Yes, VR NDT Thermographic NDT is designed to work with both composite and metallic materials, making it versatile for various applications.

What are the benefits of using thermographic NDT?

Thermographic NDT offers non-destructive defect detection, quicker inspection times, and improved understanding of material properties without causing damage.